Kazakhstan

Modular LNG (low carbon transportation fuel) Production

Applying proven liquefaction technologies and end-user applications.

- Stored at low pressure and -162° C

- 600x less volume than natural gas*

- Greater energy than diesel on a volumetric basis

Modular LNG plants are efficient and cost-effective to supply LNG

- Localizes LNG production and distribution

- Ideal for regions with limited pipeline networks

LNG is easy and safe to transport and store

- Non-explosive, non-corrosive, non-toxic; evaporates quickly and disperses if released

- Easily transported by trucks or rail hauling ISO tanks at nearatmospheric pressure

LNG industrial uses are proven worldwide

- Rail locomotives, marine vessels, mining haul trucks, long distance road haul trucks

- Kazakhstan’s national railway is currently undertaking an LNG conversion program

LNG Locomotive with Tender

LNG usage increases operating range and yields same power and torque

LNG Mine Haul Truck

Caterpillar has 10 million hours using LNG as a dual fuel

LNG Marine Vessel

LNG easily transports at near-atmospheric pressure.

Benefits of LNG Production for Central Asia

LNG reduces the carbon footprint of the equipment supplying raw materials needed to transport minerals that are critical for energy transition and renewable energy initiatives. It is more environmentally friendly & cost-effective than diesel with enhanced engine performance.

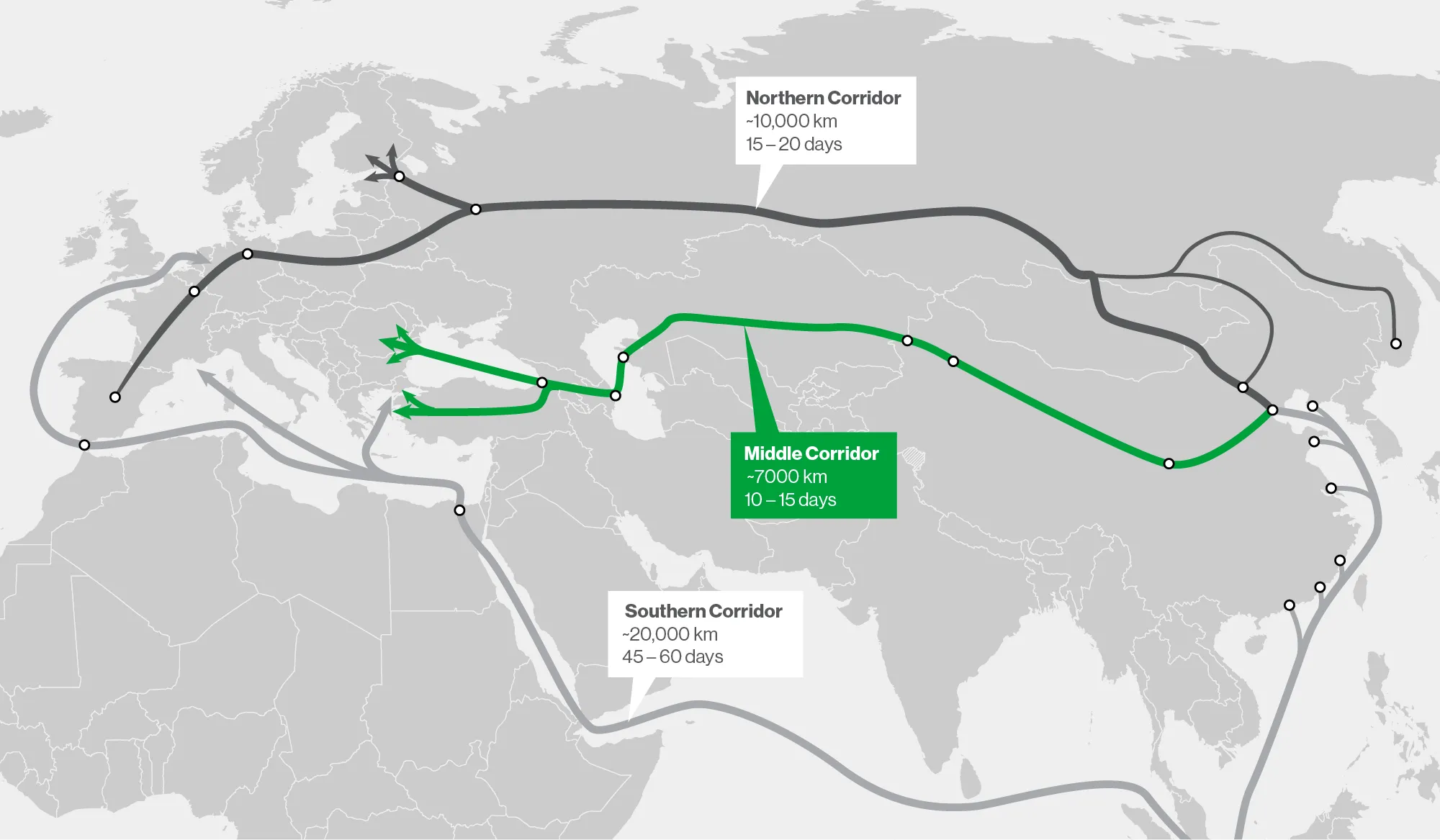

LNG Increases Clean Fuel Supply for Kazakhstan’s Strategic Middle Corridor Expansion

-

Middle Corridor is shorter and the fastest route between Asian and European markets

-

Avoids transit through Russia and the Middle East

Middle Corridor (in green) from China to Europe meaningfully reduces transport time and disruptions

30%

Lower GHG Emissions**

95%

Lower Particulate Emissions**

100%

Lower Sulphur Emissions**

+20%

More BTU energy output than diesel*

*(by weight) and improves efficiency with less frequent refueling requirements and faster freight delivery times.

**Internal calculations based on data per US EIA website

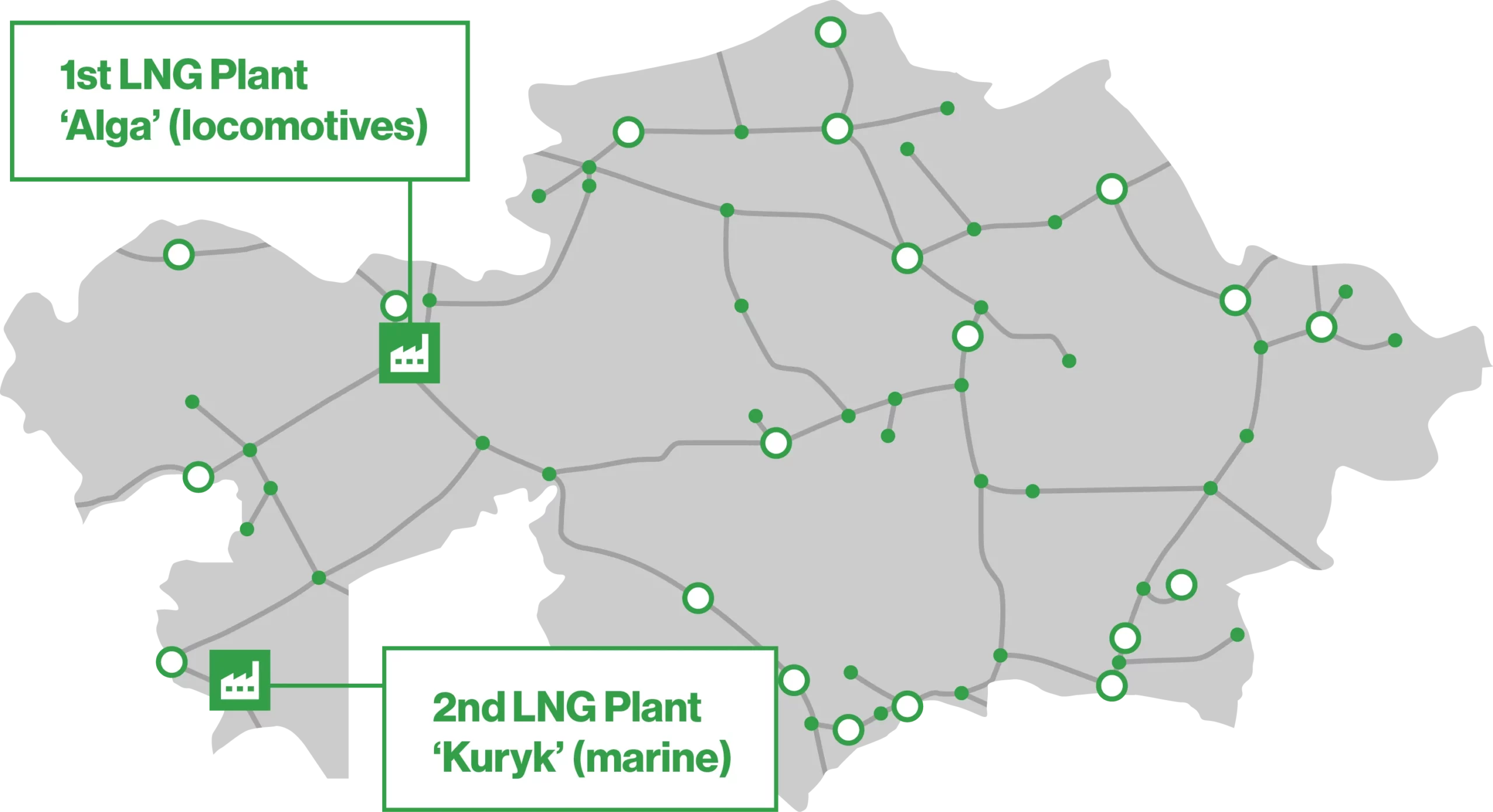

Delivering Kazakhstan's 1st LNG Production

Kazakhstan has been experiencing diesel and natural gas shortages.

- Secured 2 natural gas allocations to generate LNG

- Feed gas supplies for Alga and Kuryk LNG facilities

- Significant project milestone for 2024

- Detailed planning ongoing with 1st LNG end user KTZ (Kazakh national railway) and Wabtec

- Condor provides LNG and Wabtec* provides locomotives

- 1st LNG planned for 2H2026 from the Alga site

- Acquired industrial land and electricity allocation

- LNG facilities will be constructed in the US on modular skids for ease of installation

- Addresses Government’s critical need for additional fuel due to TITR transportation route expansion and commissioning

*Wabtec is a U.S. based locomotive manufacturer with facilities in Kazakhstan and a Fortune 500 company with a US$ 32 Billion Market Cap: NYSE:WAB

Finalizing LNG off-take volumes, delivery locations, scheduling and pricing

Energy equivalent*

1,040,000

litres/day

LNG supply for

~280

Rail locomotives

LNG supply for

~225

Large Mine Haul Trucks

C02emissions impact equivalent to

38,000

Cars removed from roads annually**

*Volume of diesel from 2 LNG feed gas allocations

**Internal calculations based on data per US EIA website

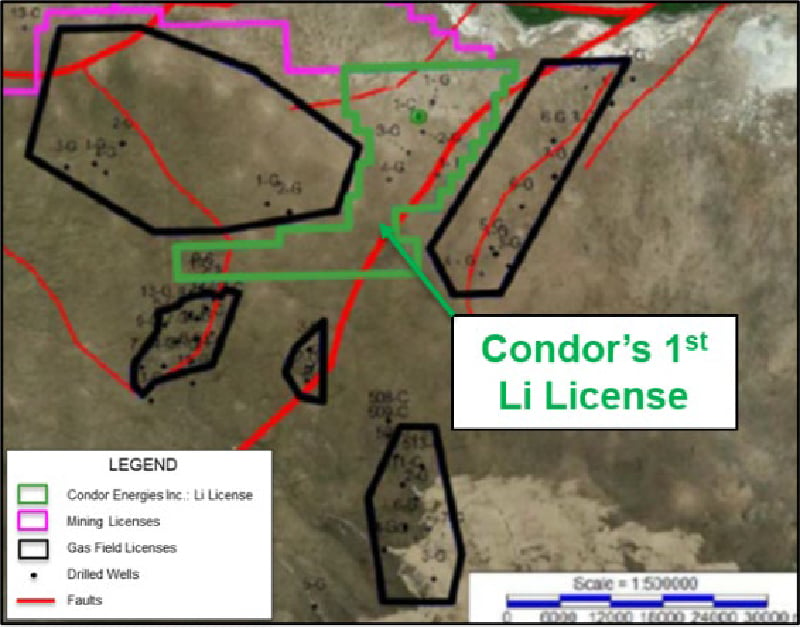

Lithium Licenses in Kazakhstan

Kazakhstan awarded Condor its first 6-year license on 37,300 hectares.

- Heavily faulted in a geothermally active region, allowing migration of mineralized brines into reservoirs

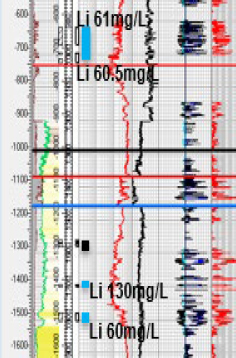

- 670-meter column of tested + untested mineral-rich brine reservoirs from historical wireline and log data, identifying lithium, cesium, manganese, rubidium & strontium

- Li concentration of 67 mg/L from Lower Carboniferous* with higher grade Devonian penetrated but not tested

- Multiple offsetting Soviet-era wells drilled to assist with regional geological characterization

Material lithium brine land position is being established.

Seeking a Second Li Brine Mining License

- Two wells previously drilled in targeted license area

- Up to 130 mg/L Li concentrations* with ~1000 meters of tested + untested lithium brine sands identified

*Concentrations as reported by the Ministry of Geology of the Kazakh Republic

Strategic Access to Asian & European Li Markets

- Neighbouring Uzbekistan has significant automotive assembly sector

- Includes large General Motors plant

- Focused on developing domestic EV manufacturing

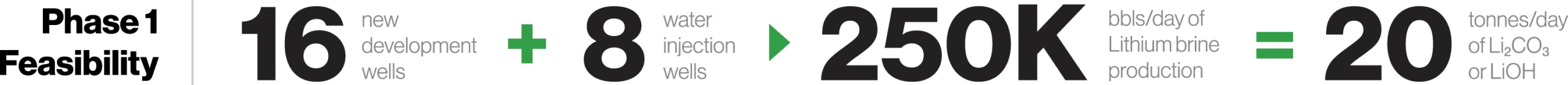

Lithium Development Path

Condor has an extensive geologic understanding of the first license's basin

- Initial development plan is to drill & test two wells

- Verify deliverability rates, confirm lateral extension and lithium concentrations in the tested + untested intervals, compile data for preparation of NI 43-101 mineral resource or reserves report

Regional Li Samples from prospective formations

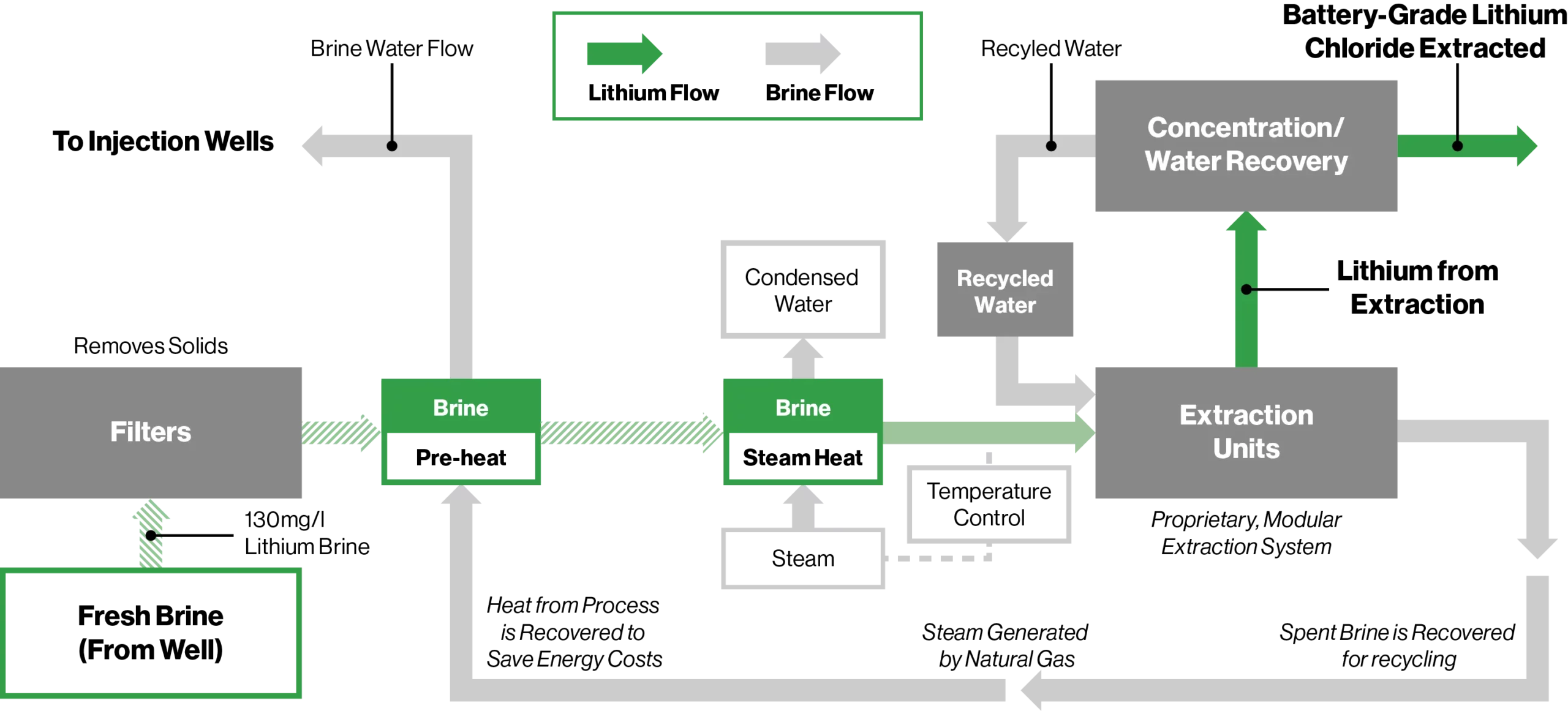

Proven Direct Lithium Extraction (“DLE”) process

Significantly lower environmental impact vs ‘salar’ evaporation ponds